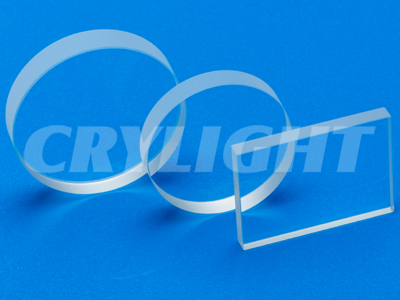

CRYLIGHT社 Window

CRYLIGHT社 Window

各モデルの抜粋仕様を下記から確認いただけます。

CaF2 WindowBK7 WindowSapphire WindowFused Silica Window

CaF2 Window

Features

The CaF2 Window is made from Calcium Fluoride material, which has transparent range from 170-7800nm. The refractive index is 1.399 at 5000nm. It has little hygroscopic susceptibility and high thermal expansion coefficient. CaF2 Windows are relatively soft and somewhat hygroscopic so polishing, coating and handling are more critical than UV Fused Silica windows. In addition, The quality of a UV window can be extremely critical, it should be of high purity and polish in order not to affect the optical system. Calcium Fluoride Windows are also applicable for a wide range of spectrum. It is particularly useful for wavelength at 2980nm laser application.

1.Useful transmission over the spectral range from 0.2 to 8.0 microns..

2.Low solubility

3.Because of its composition CaF2 window has a much longer useful life than most other materials when use in a fluorine environment.

4.We have two grades of material of CaF2 window. One is for UV application, the other is for IR application. A wide transmission range and low solubility makes it useful for many application, including:

> Mirror substrate for UV laser systems

> Substrate for manufacturing Windows, Lenses for UV and IR application

Specifications: | Material: | Calcium Fluoride |

| Diameter Tolerance: | +0.0, -0.1mm |

| Thickness Tolerance: | ± 0.2mm |

| Clear Aperture: | >80% |

| Parallelism: | 1 arc minute |

| Surface Quality: | 80/50 |

| Wavefront Distortion: | l/2 per 25mm @632.8nm |

| Bevel: | <0.25mm X 45° |

| Coating: | Uncoated |

| Part No. |

φ (mm) |

T (mm) |

| WIN3-101 |

10.0 |

0.5 |

| WIN3-102 |

12.7 |

2.0 |

| WIN3-103 |

12.7 |

3 |

| WIN3-201 |

25.4 |

3.0 |

| WIN3-202 |

25.4 |

4 |

| WIN3-301 |

38.0 |

5.0 |

| WIN3-501 |

50.0 |

3.0 |

| WIN3-502 |

50 |

4 |

BK7 Window

Features

The Window is made from BK7 material, which has transparent range from 330-2100nm. The refractive index is 1.5164 at 588nm. The BK7 window has good performance over visible and near IR spectrum for most application.

Specifications: | Material: | BK7 |

| Diameter Tolerance: | +0.0, -0.1mm |

| Thickness Tolerance: | ± 0.2mm |

| Clear Aperture: | >80% |

| Parallelism: | 1′(Standard), 10″(High Precision) |

| Surface Quality: | 60/40(Standard), 10/5(High Precision) |

| Wavefront Distortion: | l(Standard), λ/10(High Precision) per 25mm @632.8nm |

| Bevel: | <0.25mm X 45° |

| Coating: | Uncoated |

| Standard Precision |

High Precision |

| Part No. |

φ(mm) |

T (mm) |

Part No. |

φ (mm) |

T (mm) |

| WIN1-101 |

10 |

3 |

WIN1-201 |

10 |

6 |

| WIN1-102 |

12.7 |

3 |

WIN1-202 |

12.7 |

6 |

| WIN1-103 |

15 |

3 |

WIN1-203 |

15 |

6 |

| WIN1-104 |

25.4 |

3 |

WIN1-204 |

25.4 |

6.35 |

| WIN1-105 |

50.8 |

3 |

WIN1-205 |

50.8 |

6.35 |

Sapphire Window

Features

The Window is made from sapphire material, which has transparent range from 180-4500nm. The refractive index is 1.755 at 1000nm. It has strong hardness. The Sapphire window is suit for scratch resistance application with better transmission over the wide range spectrum. It can be made much thinner.

Specifications: | Material: | Sapphire |

| Diameter Tolerance: | +0.0, -0.1mm |

| Thickness Tolerance: | ± 0.2mm |

| Clear Aperture: | >80% |

| Parallelism: | 1′ |

| Surface Quality: | 80/50 |

| Wavefront Distortion: | λ per 25mm |

| Bevel: | <0.25mm X 45° |

| Coating: | Uncoated |

| Part No. |

φ (mm) |

T (mm) |

| WIN4-101 |

8 |

0.5 |

| WIN4-102 |

12 |

1 |

| WIN4-201 |

25.4 |

2 |

| WIN4-202 |

25.4 |

3 |

Fused Silica Window

Features

The Window is made from Fused Silcia material, which has transparent range from 185-2500nm. The refractive index is 1.4858 at 308nm. It has low thermal expansion coefficient. The Fused Sildica window has better performance from UV to IR spectrum. Also, it is the best choice for resistance thermal application.

Specifications: | Material: | Fused Silica |

| Diameter Tolerance: | +0.0, -0.1mm |

| Thickness Tolerance: | ± 0.2mm |

| Clear Aperture: | >80% |

| Parallelism: | 1′ (Standard), 10″ (High Precision) |

| Surface Quality: | 60/40(Standard), 20/10(High Precision) |

| Wavefront Distortion: | λ(Standard), λ/10(High Precision) per 25mm @632.8nm |

| Bevel: | <0.25mm X 45° |

| Coating: | Uncoated |

| Standard Precision |

High Precision |

| Part No. |

φ(mm) |

T (mm) |

Part No. |

φ (mm) |

T (mm) |

| WIN2-101 |

10 |

3 |

WIN2-201 |

10 |

6 |

| WIN2-102 |

12.7 |

3 |

WIN2-202 |

12.7 |

6 |

| WIN2-103 |

15 |

3 |

WIN2-203 |

15 |

6 |

| WIN2-104 |

25.4 |

3 |

WIN2-204 |

25.4 |

6.35 |

| WIN2-105 |

50 |

3 |

WIN2-205 |

50 |

10 |

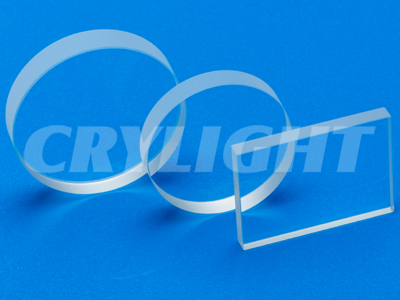

CRYLIGHT社 Window

CRYLIGHT社 Window