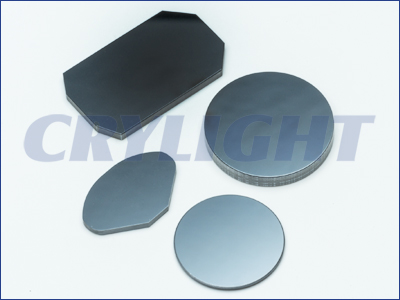

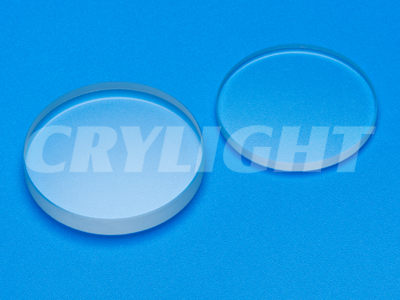

CRYLIGHT 社製 IR Window

CRYLIGHT 社製 IR Window

各モデルの抜粋仕様を下記から確認いただけます。

ZnS Window Specifications ZnSe Window Silicon Window Specifications MgF2 Window Sapphire Window Specifications CaF2 Window

Material: ZnS Diameter Tolerance: +0.0, -0.1mm Thickness Tolerance: ± 0.2mm Clear Aperture: >80% Parallelism: 1′ Surface Quality: 80/50 Wavefront Distortion: λ per 25mm Bevel: <0.25mm X 45° Coating: Uncoated

Part No.

φ (mm)

T (mm)

WIN-ZnS-101

8

0.5

WIN-ZnS-102

12

1

WIN-ZnS-201

25.4

2

WIN-ZnS-202

25.4

3

Material: ZnSe Diameter Tolerance: +0.0, -0.1mm Thickness Tolerance: ± 0.2mm Clear Aperture: >80% Parallelism: 1′ Surface Quality: 80/50 Wavefront Distortion: λ per 25mm Bevel: <0.25mm X 45° Coating: Uncoated

Part No. φ(mm) T (mm) WIN-ZnSe-101 8 0.5 WIN-ZnSe-102 12 1 WIN-ZnSe-201 25.4 2 WIN-ZnSe-202 25.4 3

Material: Silicon Diameter Tolerance: +0.0, -0.1mm Thickness Tolerance: ± 0.2mm Clear Aperture: >80% Parallelism: 1′ Surface Quality: 80/50 Wavefront Distortion: λ per 25mm Bevel: <0.25mm X 45° Coating: Uncoated

Part No.

φ(mm)

T (mm)

WIN-Si-101

8

0.5

WIN-Si-102

12

1

WIN-Si-201

25.4

2

WIN-Si-202

25.4

3

Material: MgF2 Diameter Tolerance: +0.0, -0.1mm Thickness Tolerance: ± 0.2mm Clear Aperture: >80% Parallelism: 1′ Surface Quality: 80/50 Wavefront Distortion: λ per 25mm Bevel: <0.25mm X 45° Coating: Uncoated

Part No. φ (mm) T (mm) WIN-MgF2-101 8 0.5 WIN-MgF2-102 12 1 WIN-MgF2-201 25.4 2 WIN-MgF2-202 25.4 3

Material: Sapphire Diameter Tolerance: +0.0, -0.1mm Thickness Tolerance: ± 0.2mm Clear Aperture: >80% Parallelism: 1′ Surface Quality: 80/50 Wavefront Distortion: λ per 25mm Bevel: <0.25mm X 45° Coating: Uncoated

Part No.

φ (mm)

T (mm)

WIN4-101

8

0.5

WIN4-102

12

1

WIN4-201

25.4

2

WIN4-202

25.4

3

Material: Calcium Fluoride Diameter Tolerance: +0.0, -0.1mm Thickness Tolerance: ± 0.2mm Clear Aperture: >80% Parallelism: 1 arc minute Surface Quality: 80/50 Wavefront Distortion: λ/2 per 25mm @632.8nm Bevel: <0.25mm X 45° Coating: Uncoated

Part No. F (mm) T (mm) WIN3-101 10 0.5 WIN3-102 12.7 2 WIN3-103 12.7 3 WIN3-201 25.4 3 WIN3-202 25.4 4 WIN3-301 38 5 WIN3-501 50 3 WIN3-502 50 4